Laser My Wheels

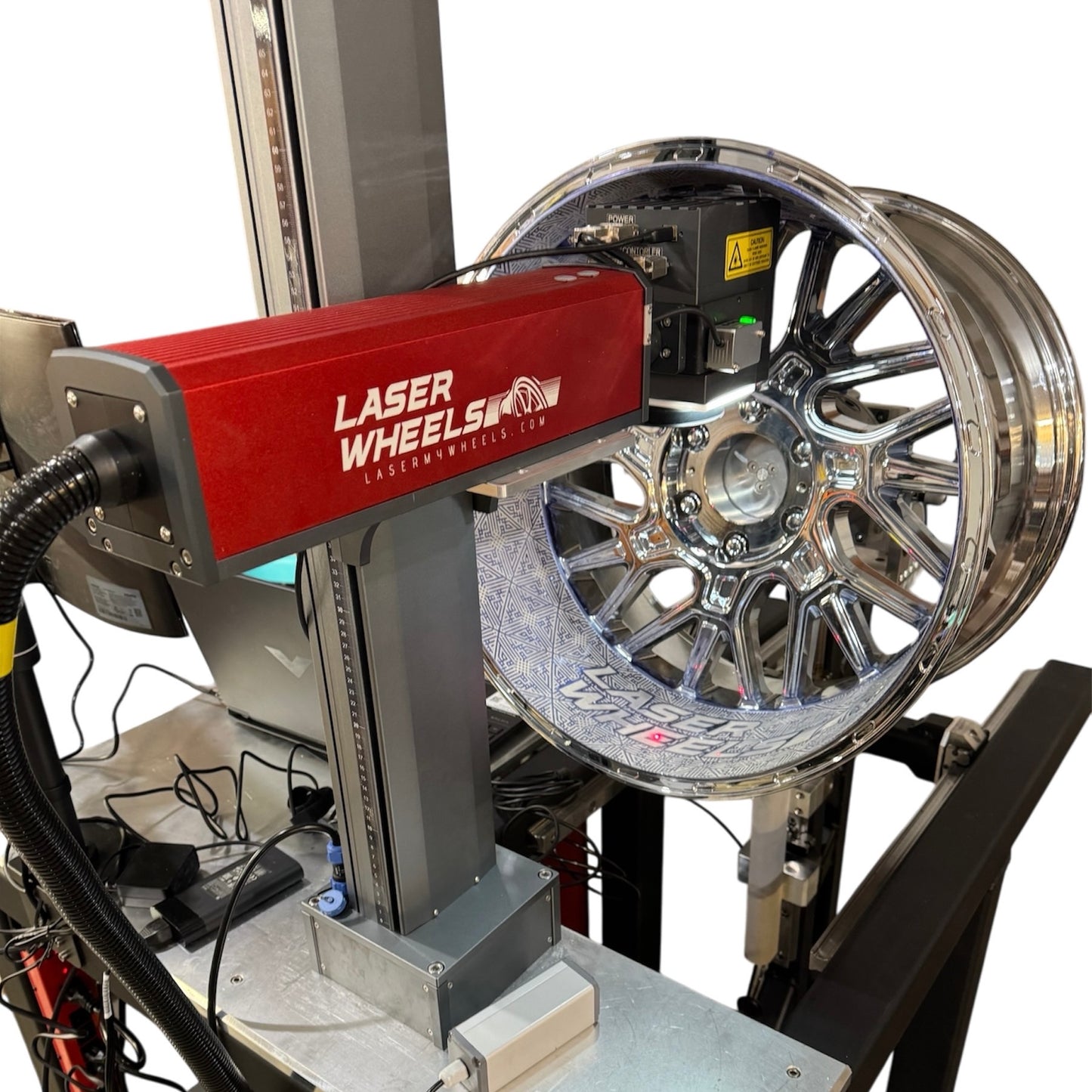

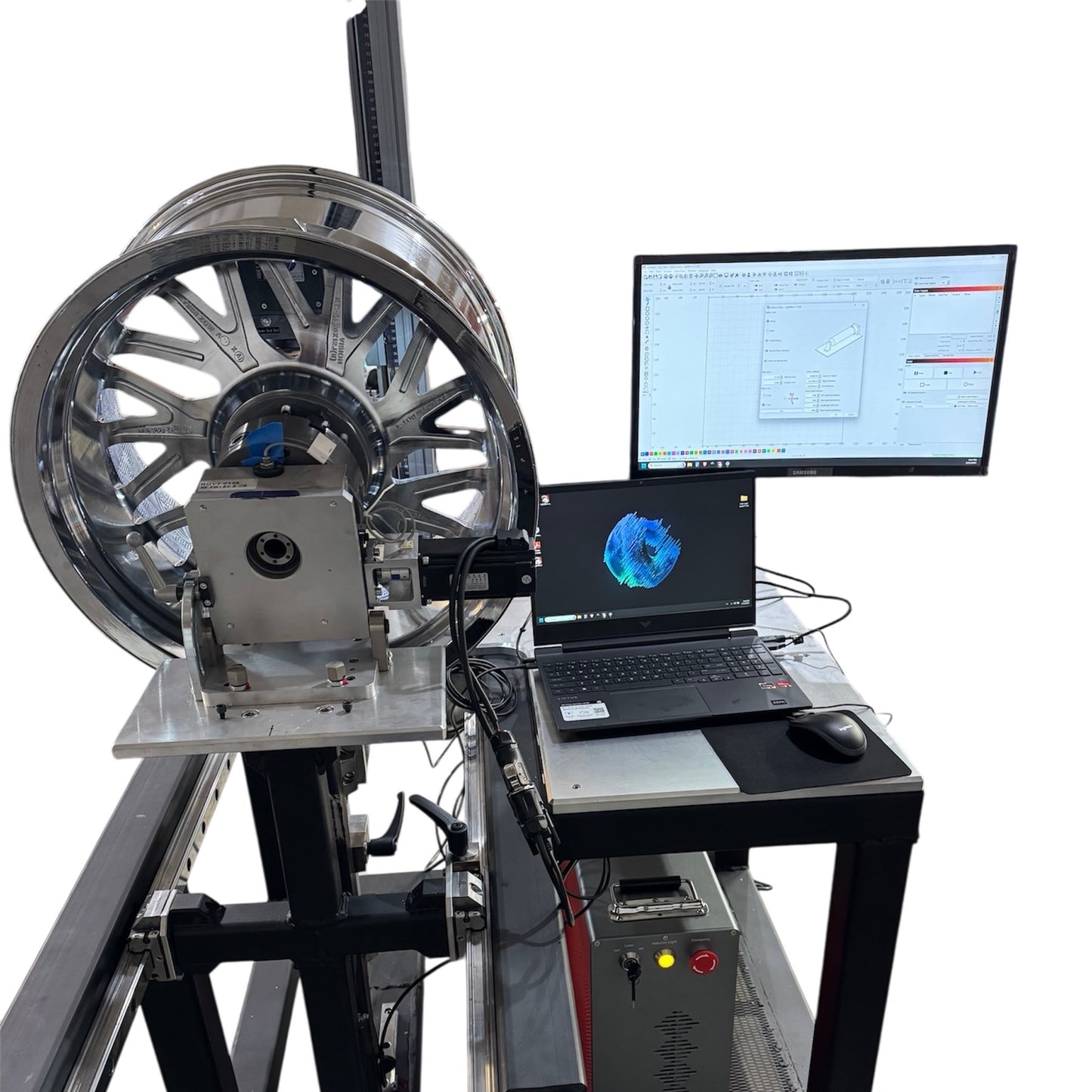

Laser My Wheels Gen. 1 Wheel Engraving Laser Workstation

Laser My Wheels Gen. 1 Wheel Engraving Laser Workstation

Couldn't load pickup availability

LAUNCH PROMOTION: Try before you buy! If you are interested in seeing how this laser system can work for you and your business, check out our FREE Sample Engraving Program!

Description

Description

Our flagship wheel engraving workstation allows you to offer laser engraved customization of wheels to your clientele!

Open up brand new markets and revenue streams in ways that were not previously available!

Available in multiple configurations, including a workstation-only option if you would like to add your own laser and/or rotary devices!

Deposit Information

Deposit Information

Minimum 25% deposit required to begin manufacture of your wheel engraving laser workstation order.

This deposit secures your order, placing your machine(s) in our manufacturing queue.

- Estimated manufacturing lead time currently 6-8 weeks.

ACH, or direct billing options are available for placing a deposit on your very own wheel engraving laser workstation!

Remaining balance due in full prior to shipment of your completed order.

Workstation Specifications

Workstation Specifications

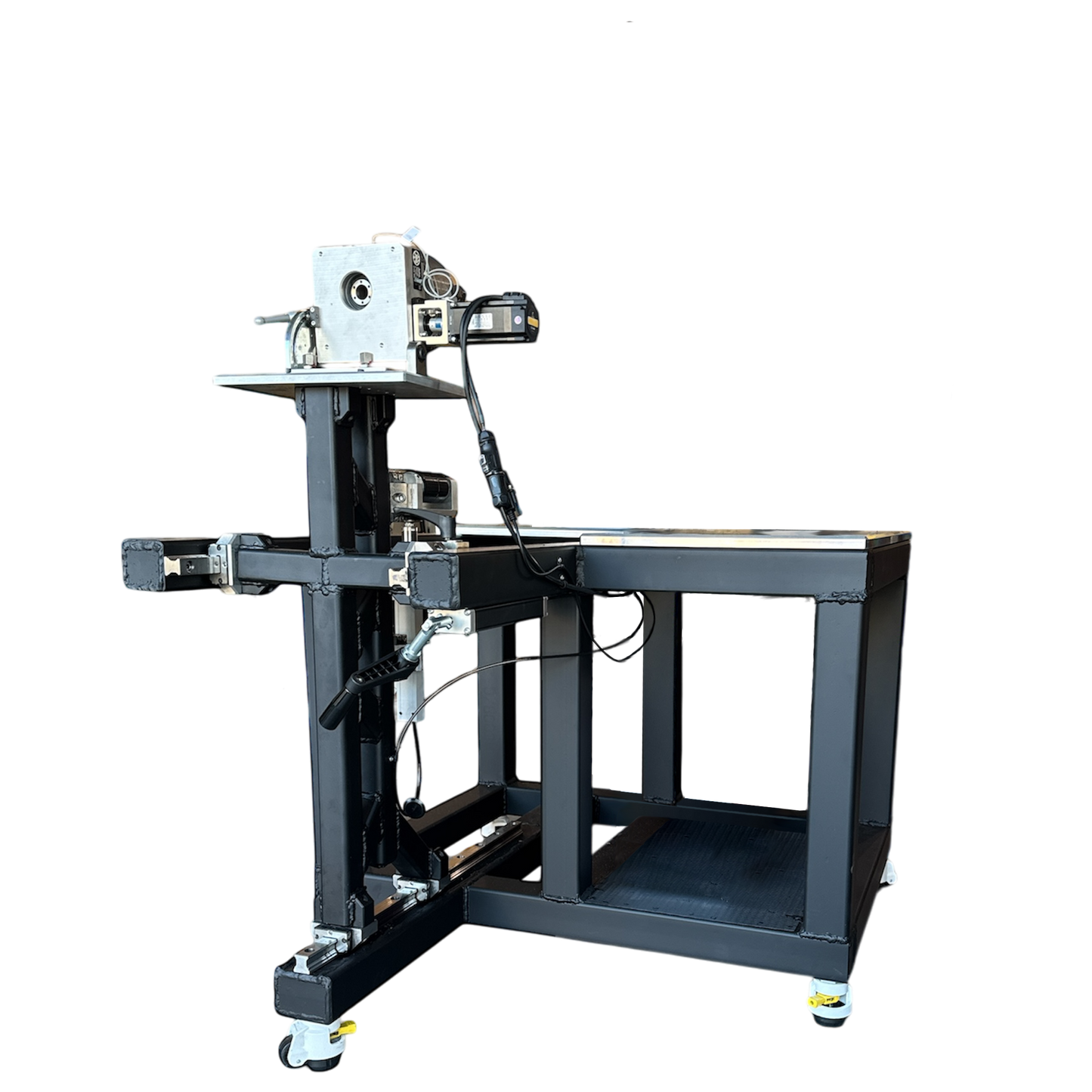

Overview:

- Workstation Dimensions: 42in W x 40in D x 60in H

- Workstation Weight: 600lbs (362.87kg)

- Minimum Diameter: 15in (all rotary options)

- Maximum Diameter: 32in (w/Stage 3 Rotary)

- Manufacturing Leadtime: 6-8 weeks

- Deposit Required: Minimum 25%, Optional

- Patent: Pending

Workstation Features:

- 3/16" steel frame construction

- Machined aluminum tabletop

- Casters with adjustable leveling feet

- Manual hydraulic wheel support, with roller bearings

- Support tower mounted to linear guide bearings

- Machined aluminum rotary mount plate bolts to the support tower.

- Can be drilled and tapped to mount many different styles of rotaries, or other work handling devices

Laser System Specifications

Laser System Specifications

Overview:

- Laser System: Optional

- Monitor: Included

- Computer: Not Included

- Control Software: LightBurn

- Laser Source: JPT M7 200W/350W MOPA Fiber; Optional

- Scan Head: Galvo

- Compatible Lenses/Marking Area: 110*110mm, 150*150mm, 175*175mm, 200*200mm, 300*300mm

- Lens Included: 1 Focal Lens included w/laser system; Additional sizes available.

- Camera: Included w/Laser System; Standard

- Z-Height: 800mm (31.49in)

- Power Requirements: 15A/120V (Dedicated, APC back-up recommended)

CNC Rotary Specifications

CNC Rotary Specifications

Overview:

- Rotary Device: Optional

- Stage 1 Rotary Work Handling: 15in (35.56cm) through 20in(45.72cm); Tested through 60 lbs (24.94kg).

- Stage 2 Rotary Work Handling: 15in (35.56cm) through 24in(60.96cm); Tested through 80 lbs (34.01kg).

- Stage 3 Rotary Work Handling: 15in (35.56cm) through 32in(81.28cm); Tested through 110 lbs (47.63kg).

- Rotary Fixturing Kit: Optional; Sold Separately

Rotary Features:

- Self-centering 3-jaw chuck included

- Can be used in any position

- Fully sealed aluminum housing

- Low maintenance thanks to oil bath

- Cross roller bearings for high loads and strong reversing

- Virtually backlash-free worm drive, adjustable via eccentric cam, with low-wear material combination

- Computer-optimized worm drive for quiet running and increased drive efficiency

- Large spindle opening

- Dividing spindle with indexing slot

- Optionally available: end switch that acts directly on the worm gear and motor flange systems for attaching various motors

Class IV Laser Safety Information

Class IV Laser Safety Information

Our Wheel Engraving Laser Workstations utilize Class IV MOPA Fiber Laser Systems.

While the lasers are in operation, Personal Protective Equipment (PPE) should be implemented, to include any combination of the following:

- Laser safety glasses, goggles, or face shields rated for 1064nm wavelength exposure

- Where in operation in common use or trafficked areas, barrier panels or curtains are strongly encouraged.

- These products are engineered for protective use with Class IV laser systems to create a controlled-access area that permits the safe operation of such laser equipment

Each laser system comes with two pair of laser safety glasses, rated for 1064nm wavelength. Additional glasses may be purchased here.

In addition to PPE, avoidance of flammable, or combustible materials in the operations area of a Class IV laser system is strongly advised.

The following procedures are also strongly advised:

- Avoiding skin contact with the beam path

- Operate Class IV lasers in a well ventilated area

- Include the use of fume extraction equipment while in operation

- If possible, operate lasers in a controlled access environment by authorized personnel who are trained on the subject of laser safety

You can view our Laser Safety Product offerings here

Share